Blogs

The importance of quality control in construction projects

Do you want your construction project to meet the required standards, be safe for use, and exceed your client’s expectations? Then quality control is essential! In this article, we will discuss this part of project management in construction.

What is quality control in construction?

Quality control in construction projects is the process of inspecting, testing, and evaluating construction materials, products, and works to ensure that they meet established standards and specifications.

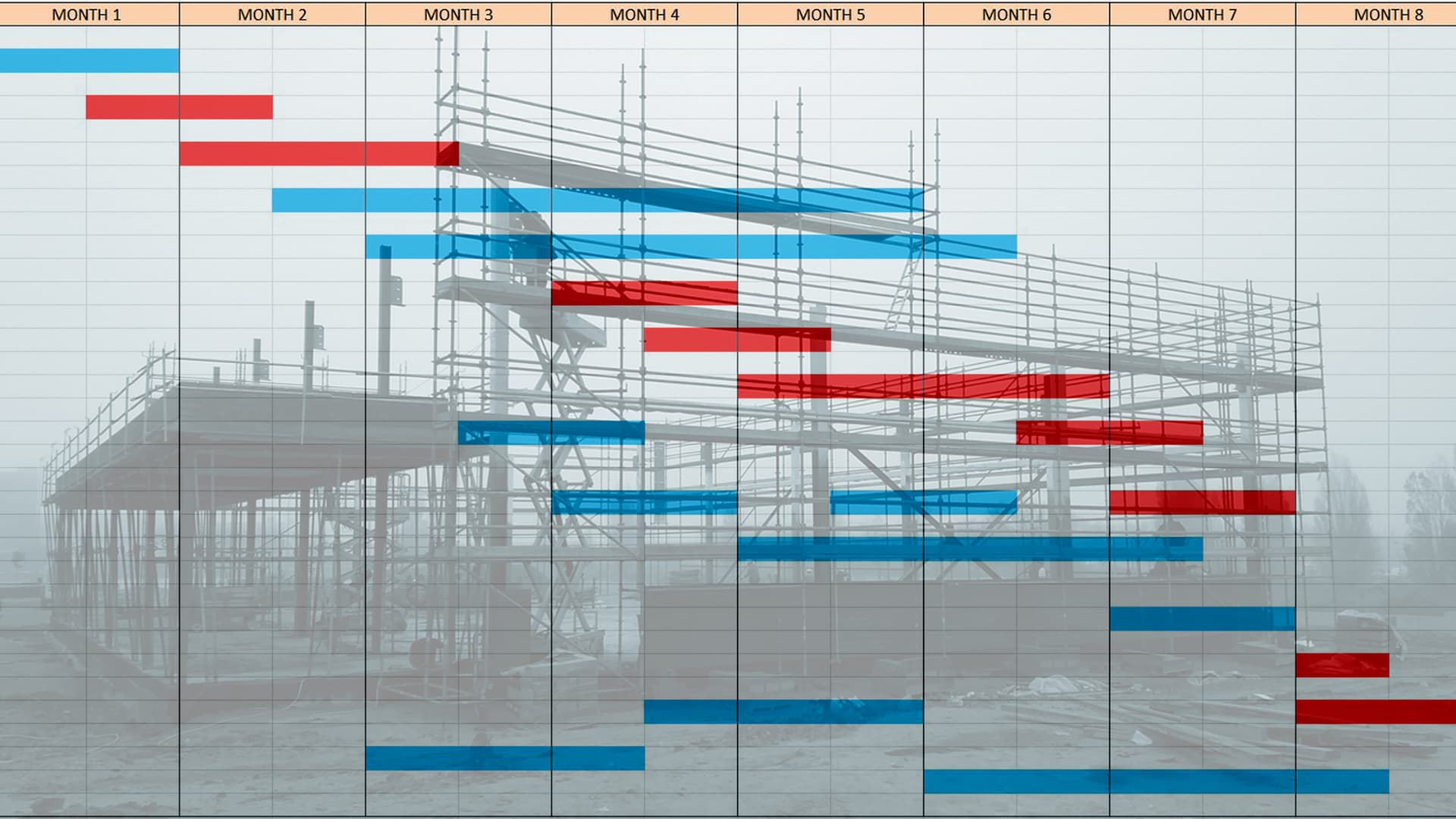

It includes monitoring and adjusting processes during all phases of the project, from design to completion. Quality control aims to identify and resolve potential problems early so that the result is of the right quality.

Quality control focuses on aspects such as:

- Compliance with building regulations and standards.

- Use of appropriate materials and products.

- Skillful execution of work.

- Timely delivery within budget.

- Client satisfaction.

By implementing an effective quality control system, you and your construction team minimize the chances of mistakes, delays, and budget overruns. It also helps strengthen your company’s reputation and gain the trust of clients.

Why is quality control important?

Quality control is important in construction projects for several reasons:

1. Ensuring safety

The safety of users and occupants is paramount. You guarantee that your building meets safety standards by carrying out strict quality control. And that it can withstand various loads and environmental factors. This prevents potentially dangerous situations and liability issues.

2. Increase customer satisfaction

Clients expect a high-quality end product that meets their requirements. Quality control ensures that the project is consistent with your client’s specifications and expectations. Satisfied clients lead to positive word-of-mouth, repeat business, and a strong reputation in the market.

3. Control costs

Errors and defects that you discover late in the construction process can be expensive to fix. By carrying out quality checks from the outset, you identify and fix problems early, which reduces costs in the long run. It also prevents delays and fines for not meeting standards or deadlines.

4. Compliance with laws and regulations

Construction projects must comply with numerous laws and regulations, such as building codes, environmental standards, and labor laws. Quality control helps ensure that your construction project meets all relevant requirements, reducing your risk of legal problems and fines.

5. Competitive advantage

Companies known for their high-quality standards and consistent delivery of quality projects stand out from their competition. This leads to more orders, higher profit margins, and a sustainable competitive advantage in the market.

Parties involved in quality control

Quality control in construction projects is a joint effort involving several parties.

1. Project manager

As a project manager, you are ultimately responsible for the overall quality of the project. You set quality objectives, develop a quality plan, and ensure its implementation. You coordinate the efforts of all parties involved and monitor progress to ensure that the entire project meets quality standards.

2. Quality control team

A dedicated quality control team carries out inspections, tests, and audits during different phases of the project. They identify deviations from standards and propose corrective actions. The team works closely with the project manager and other departments to ensure quality.

3. Designers and engineers

Designers and engineers are responsible for developing detailed plans and specifications that meet quality standards and requirements. They work with the quality control team to ensure that the design is feasible, sustainable, and safe.

4. Contractors and subcontractors

Contractors and subcontractors carry out the actual construction work according to the plans and specifications. They are responsible for using appropriate materials, following proper procedures, and training their employees to meet quality standards. Regular communication and coordination with the project manager and quality control team are essential.

5. Suppliers

Suppliers play a crucial role in providing high-quality materials and products for the construction project. They must meet quality specifications and deliver on time. Careful selection and monitoring of suppliers contribute to the overall quality of the project.

6. Clients and end-users

Although clients and end-users are not directly involved in quality control processes, their input and feedback are valuable. Their requirements and expectations form the basis for the project’s quality goals. Regular communication and customer involvement ensure alignment and satisfaction.

Tips for quality control in construction

1. Engagement of team members

One of the most important aspects of quality control is the deployment of the right team. Ensure that each team member is qualified for his or her task and that each is aware of quality standards and procedures. Regular training and refresher courses help keep the skills of the team up to date.

2. Internal communication

Communication is also crucial. Hold regular discussions that address quality issues and encourage team members to report any problems or areas for improvement. By promoting open and transparent communication, you will be better placed to identify and address potential quality issues early on.

3. Deploy technology

Technology can be a valuable tool in quality control. Consider using project management and quality control software to streamline processes and improve communication. Such tools help track inspections, identify problems, and generate reports.

You can also consider using advanced technologies such as drones, 3D scanners, and sensors to monitor the quality of work. These tools provide detailed and accurate data that complement or replace manual inspections, saving you time and resources.

4. Safety

Safety is a top priority in the construction industry and is closely linked to quality control. Ensure that all team members are properly trained in safety procedures and have the right personal protective equipment (PPE). Conduct regular safety inspections and address any problems immediately.

Involve subcontractors and suppliers in your safety initiatives as well. Make sure they are aware of the desired safety standards and expectations and that they adhere to them. A safe workplace contributes to the overall quality of your construction project and protects your team and company from potential liability issues.

5. Compliance with laws and regulations

Construction projects are subject to a wide range of laws and regulations, ranging from building codes to environmental standards. It is essential to keep abreast of these requirements and ensure that your construction project complies with them.

Designate a team member as responsible for compliance and make sure they keep abreast of regulatory changes. Conduct regular audits to check that all requirements are met and document your efforts carefully. Failure to comply with laws and regulations may lead to fines, delays, or reputational damage.

6. Insurance coverage

Despite all quality control efforts, things can still go wrong in a construction project. Make sure you are adequately insured against damages. Determine the right coverage based on the specific risks of your project.

Also, consider having certain requirements for insurance by subcontractors and suppliers. This helps reduce your risks and ensure that all parties are adequately protected.

7. Testing

Testing is a crucial part of quality control in construction projects. Run regular tests during different phases of the project to identify and address any problems early on.

Some examples of testing include:

- Material testing: Check that the materials used meet the required specifications and standards.

- Functional testing: Test systems such as electrical, plumbing, and HVAC to ensure they are functioning properly.

- Integration testing: Check how different systems and components work together as a whole.

- Inspection tests: Perform visual inspections to assess the overall quality and finish of the work.

Document all test results carefully, use this information to make improvements, and check whether the adjustments are sufficient. This will help you avoid future problems.

Conclusion

Quality control in construction projects is a continuous process that requires the commitment and cooperation of all parties involved. By prioritizing quality and following a structured approach, you minimize risks, increase customer satisfaction, and strengthen your company’s reputation.

Investing in quality control pays off in the long run, both for individual projects and for the success of the organization as a whole. As a project manager, you play a key role in ensuring quality in construction projects.

By promoting a culture of quality, setting clear goals, and working closely with all stakeholders, you will be able to deliver projects that meet the highest standards and exceed expectations.

Would you like to discover how Simjo supports your construction project?

Simjo is project management software specially developed for project managers and project teams in construction. Start for free and discover the possibilities of Simjo construction project management software!